Thermablok® Aerogel Insulation

Thermablok

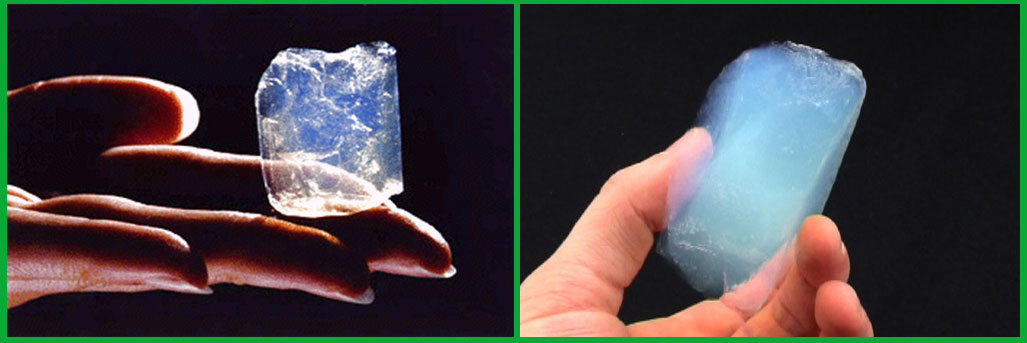

Aerogel, also referred to as “frozen smoke,” has been difficult to adapt to most uses because of its compressibility and fragility. Compressibility of an insulating material of course destroys its insulating effectiveness. The Aerogel in Thermablok material overcomes this by using a proprietary thermal process to strengthen its formula such that it is by far the least compressible of all other known aerogels. This allows it to be bent or be under great pressure while still retaining its amazing insulation properties.

Now available to the building industry, just one thin Thermablok Aerogel Insulation Strip®(pat.pend) added to the edge of each stud before adding gypsum or sheeting is all that is needed to tackle thermal bridging problems and contribute towards maximum R-value.

Thanks to its hydrophobic properties, Thermablok will not age, mold, or mildew. Thermablok uses an amorphous silica (distinctly different from crystalline silica) aerogel insulating material which is environmentally safe and recyclable.

Thermablok aerogel insulation is made up of a composite material consisting of aerogel embedded within a fiberglass type matrix.

The first video below, from the Lawrence Livermore National Laboratories, demonstrates aerogel and its properties. The second video shows how aerogel can be used to address energy issues in the cities of tomorrow. The third video shows how Thermablok Aerogel Insulation Strips virtually eliminate thermal bridging using a block of dry ice and a thermal camera.

| Frozen Smoke Video | Aerogel Ecopolis | This is an example of virtually eliminating thermal bridging in construction with Thermablok Aerogel Insulation Strips (patent pending). |

This is an example of virtually eliminating thermal bridging in construction with Thermablok Aerogel Insulation Strips (patent pending).

Aerogel Ecopolis

Frozen Smoke Video

What is an Aerogel?

To give you an idea what makes aerogel a special material for so many uses, it is instructive to provide some structural and functional definitions.

What is a Gel?

Many chemical reactions that involve polymerization of molecules form dispersed nanoparticles in solution, particularly those that occur in three dimensions via cross-linking between growing solid chains. A gel precursor is a chemical or mixture of chemicals that can be activated toward molecular nucleation into small colloidal particles. A gel forms when a solution of these dispersed nanoparticle colloids (also called “sols”) are induced to form a semi-solid form via interparticle condensation. Sols can be stable for very long periods of time if the solution conditions are not conducive to interparticle condensation. When a catalyst is added to create the appropriate conditions for interparticle condensation, the viscosity of the solution can increase very rapidly as the semi-solid state is reached.

What is an Aerogel?

What are Aerogels made of?

Aerogel Case Studies

Aerogel Thermal Insulation Case Studies

Thermablok® Thermal Insulation Installation Suggestions

Easy Installation for Residential and Commercial Applications

| Thermal Strip Insulation Thermablok may be installed either on the exterior or interior side of the wall framing. Insulate the full length of framing members. Apply to all wall, floor or ceiling framing edges: headers, footers, trusses, window and door frames, floor joist and roof rafters. |

| Blanket Insulation Do not install Thermablok and new siding over walls that have deteriorated from moisture, insects, etc. Repair unsound walls prior to proceeding. Plan and coordinate the thermal bridging barrier insulation work to minimize the generation of off-cuts and waste. |

Below you can download Thermablok PDF specification/guideline documentation

Thermablok Thermal Insulation Specifications

Thermablok Physical Properties

| 0.40in(10mm)Thickness | 390F(200C)Max Temp | WhiteColor |

| 9.4 lb/Ft3Density | R-Value=10.3/inchR Value | YesHydrophobic |